As California’s regulations around vehicle emissions remain uncertain, one thing has become clear: centralized hydrogen production alone won’t meet the rising demand for clean fuel.

To support meaningful and timely decarbonization, we need hydrogen infrastructure that is modular, distributed, and rapidly deployable. Small-scale hydrogen production near the point of use offers a more cost-effective and operationally resilient path forward for fleets, municipalities, and industry alike.

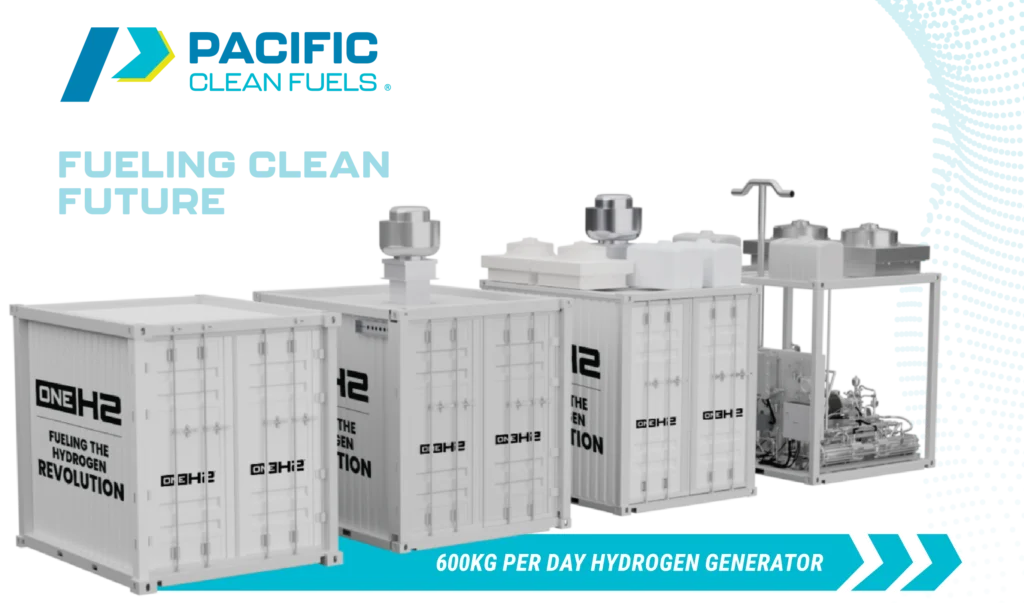

At Pacific Clean Fuels, our strategy centers on localized hydrogen ecosystems that eliminate traditional bottlenecks and unlock immediate value. Through key partnerships, including our work with OneH2, we’re delivering practical clean hydrogen solutions where they’re needed most.

The Limitations of Centralized Hydrogen Production

Historically, hydrogen fuel has been produced at large industrial plants and distributed via long-haul logistics. While functional for high-volume supply chains, this approach creates significant challenges:

- High transport costs that inflate per-kg fuel prices.

- Limited flexibility, slowing the rollout of new fueling locations.

- Delivery risks due to supply chain disruptions, especially in remote or high-demand areas.

- Long permitting timelines and capital requirements for large-scale facilities.

These issues disproportionately affect medium-duty and off-grid users, such as public works fleets, ag producers, and warehouse operators, who need clean fuel solutions now, not years from now.

Small-Scale Hydrogen: A Practical, Scalable Alternative

Localized hydrogen generation offers a solution that is cost-aligned, rapidly deployable, and strategically flexible.

Technologies like electrolysis and steam methane reforming (SMR) are being integrated into modular platforms that can be deployed near or on-site. PCF and its partners are leveraging this distributed model to deliver hydrogen where it’s needed most—with significant cost and reliability advantages.

Key Benefits

- Reduced Fuel Delivery Costs: Local production eliminates the need for long-distance fuel transport, cutting both emissions and logistics expenses.

- Improved Reliability: By decentralizing the supply chain, users reduce their dependence on third-party delivery schedules and minimize exposure to route disruptions.

- Lower Upfront and Lifecycle Costs: Compared to large-scale refueling infrastructure, localized systems involve

- Lower capital investment

- Shorter permitting and deployment timelines

- Scalable deployment matched to fuel demand

- Faster Market Entry: With mobile fuelers and Pop-Up Fueling Centers, businesses can get operational in weeks, not years, and respond to regulatory or market shifts with agility.

Real-World Deployment: Where Hydrogen Has the Greatest Impact

Localized hydrogen production is already making a tangible difference across a variety of industries and sectors.

Municipal & Commercial Fleets

City and regional fleets—including transit, sanitation, and delivery—are using mobile hydrogen fueling to meet zero-emission mandates without permanent infrastructure buildout. A comparative cost analysis from LIFTE H2 shows that, over a 10-year period, mobile hydrogen refueling can deliver a 35% lower levelized cost than fixed stations in some cases.

Agricultural Fueling in Remote Areas

Farmers and producers often operate far from central fuel sources. Small-scale hydrogen production and mobile delivery are bridging the infrastructure gap for off-grid fueling, fertilizer production, and seasonal operations. Research from Washington State University confirms the technical feasibility of hydrogen in remote agricultural energy systems.

Industrial and Warehouse Hydrogen Usage

Hydrogen-powered forklifts, heavy equipment, and stationary systems require reliable fueling without sacrificing floor space or uptime. PCF and OneH2 are enabling industrial clients to access near-site fueling with modular systems, scaling fuel access without long-term facility overhauls.

PCF’s Strategic Hub-and-Spoke Model

To enable regional coverage with local impact, Pacific Clean Fuels is developing a hub-and-spoke distribution model grounded in scalable production and agile delivery.

- Bakersfield Production Facility: Up to 2,000 kg/day capacity via SMR with expansion potential.

- Regional Micro-Terminals

- Fresno: Supporting Central Valley agriculture

- Fontana: Serving warehousing and SoCal logistics

- Stockton: Powering Bay Area fleets and transit

These strategically located terminals feed a growing network of mobile hydrogen trailers, Pop-Up Fueling Centers, and modular production units, forming a flexible, responsive clean fuel ecosystem across California.

A New Model for Transitioning to Clean Energy

Small-scale hydrogen production is not a temporary workaround. It’s an essential piece of long-term infrastructure that enables:

- Faster adoption of zero-emission technologies

- Smarter capital deployment

- Resilient, decentralized energy systems

With policy pressure intensifying and demand growing, organizations need infrastructure that can scale on their timeline, not one dictated by the construction cycle of centralized plants.

If you’re ready to bring the future of hydrogen closer to home, contact us today and learn how small-scale production can revolutionize your operations.